Different methods for the production of oil

There are several methods to extract oil from seeds, nuts and other agricultural products. In order to clarify the question of which process is the best, we will look at the most common of them in detail and contrast them with the processes we use to produce the organic oils for our capsules at CapsOleum.

Conventional methods for oil extraction

Solvent extraction

Solvent extraction is a process in which the oil is separated from the seed by chemical means. Many conventional, cheap vegetable oils are produced using this process, including many of the sunflower oils available in any supermarket. Solvent extraction works as follows:

- The seed is ground to a fine powder.

- A solvent, usually hexane, is added to chemically separate the oil from the rest of the powder.

- The liquid mixture of oil and solvent is separated from the solid part.

- The solvent is evaporated or the mixture is distilled to obtain the oil.

Solvent extraction is the process with the highest yield and efficiency, as up to 99% of the oil content can be recovered from the seeds. However, there are many risks associated with this process. The most obvious of these is probably the processing of the food with toxic substances such as hexane, which can cause nerve damage.

Officially, the solvents are completely removed from the oils, but it cannot be ruled out that a small part of the substances remains in them. Of course, this is of little concern when you look at the concentration of substances in a single bottle, but over the long term, the consumption of oils produced in this way cannot be healthy. The valuable substances in the oil are also attacked or completely destroyed by this process.

Expeller pressing

At first glance, expeller pressing resembles cold pressing, but there is one crucial difference: the temperature. The process itself works mechanically, but chemicals are often added to the seeds to increase the yield. These are the steps the seeds go through on their way to becoming oil during expeller pressing:

- The seed is heated strongly to facilitate pressing, as this makes it easier for the oil to separate from the solid rest of the seed later.

- The oil is pressed out of the seed. Again, heat is generated because the seed is subjected to such immense forces. For reasons of efficiency, reducing the speed of the presses, which could reduce the temperature development, is avoided, because it would also reduce the amount of oil produced per minute.

The heat generated during expeller pressing is such a problem because it attacks or destroys important ingredients of the oils. Especially for oils that are taken for their active ingredients, this process is absolutely not recommended. Unfortunately, it happens again and again that oils produced with the help of expeller pressing are advertised as healthy and sold at similarly high prices as products of much higher quality.

Oil extraction process used by CapsOleum

Cold pressing

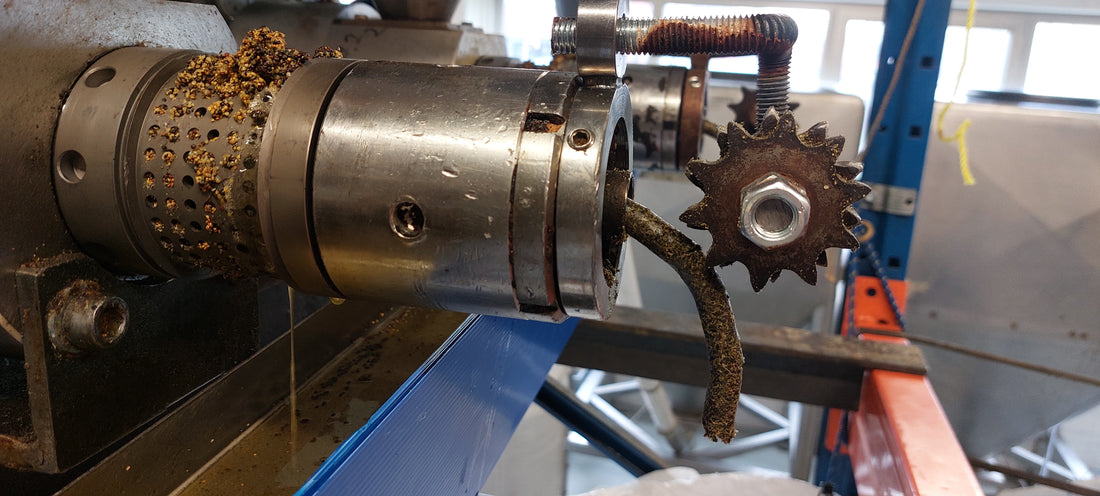

In principle, cold pressing is very similar to expeller pressing. In both processes, the oil is extracted with the help of mechanical pressing. However, no additional heat is added to the seeds at any time during cold pressing. In addition, no chemicals of any kind are added to CapsOleum's oils. The goal here is to separate the oil from the solids as gently as possible. This is ensured with the following steps:

- The seeds are pressed by a screw press, i.e. a very slowly rotating screw, whereby the speed at which it rotates is throttled to such an extent that as little heat as possible is generated during pressing.

- The resulting press cake, i.e. the solid residue of the seed, is collected and processed into either flour or animal feed.

The cold pressing process used by CapsOleum to extract the oils is the process that protects by far the most of the healthy and valuable ingredients of the oils. Due to the gentle procedure and the slow pressing, the process takes longer, but it results in the highest quality product. The oils in capsules from CapsOleum are produced by the Allgäuer Ölmühle in Kempten in the south of Bavaria.

Refining

Most oils are refined after pressing. Here, too, there are various processes that can have an impact on the quality of the products.

Conventional refining

Conventional oils are usually refined using the following processes, although there may be differences in processes and methods from manufacturer to manufacturer.

- Degumming: The oil is treated with acids or enzymes to remove mucilage.

- Neutralization: The oil is treated with alkaline substances, for example sodium hydroxide, to remove free fatty acids. This is to improve the shelf life of the oil.

- Bleaching: The oil is bleached with activated carbon, clay or similar substances to change the color of the oil and remove odors by removing certain pigments from the oil.

- Deodorization: The oil is heated in a vacuum to remove final odors and give the oil a neutral taste.

The fact that these processes can impair the quality of the oil and destroy healthy ingredients does not need to be explained further.

Refining process used by CapsOleum

With CapsOleum's oils, the oils are filtered exclusively through many layers of special cloths. The aim of this is to filter out turbidity and waxes that would otherwise give the oils a milky appearance. All the valuable ingredients of the oils are retained and no chemical substances are added.

Conclusion

Oil recovery is a very complex subject, and there are countless processes and combinations of methods to accomplish just that.

However, there are clearly better and worse options. Most conventional processes not only result in poor quality products, but due to the generous use of heat and chemicals, they are also significantly more harmful to the environment than the cold pressing and subsequent filtering that we at CapsOleum use to manufacture our products.

We hope that this article has shed some light on the often rather dark jungle of oil production and that you will be able to choose the oils you consume in the future with a good understanding of the various processes.